How a Formula becomes a Product

It may take years of testing, including both clinical studies as well as with test subjects, to finally get the formula you want but that is only the beginning. The process of a formula becoming an actual product is arduous and depends on the product category, however, it is none the less relatively straight forward. Understanding these steps are critical in allowing you to put together a time line; refine your budget and to do cash flow projections.

Read more: If You Need Expertise – Hire an Expert – The Scientist

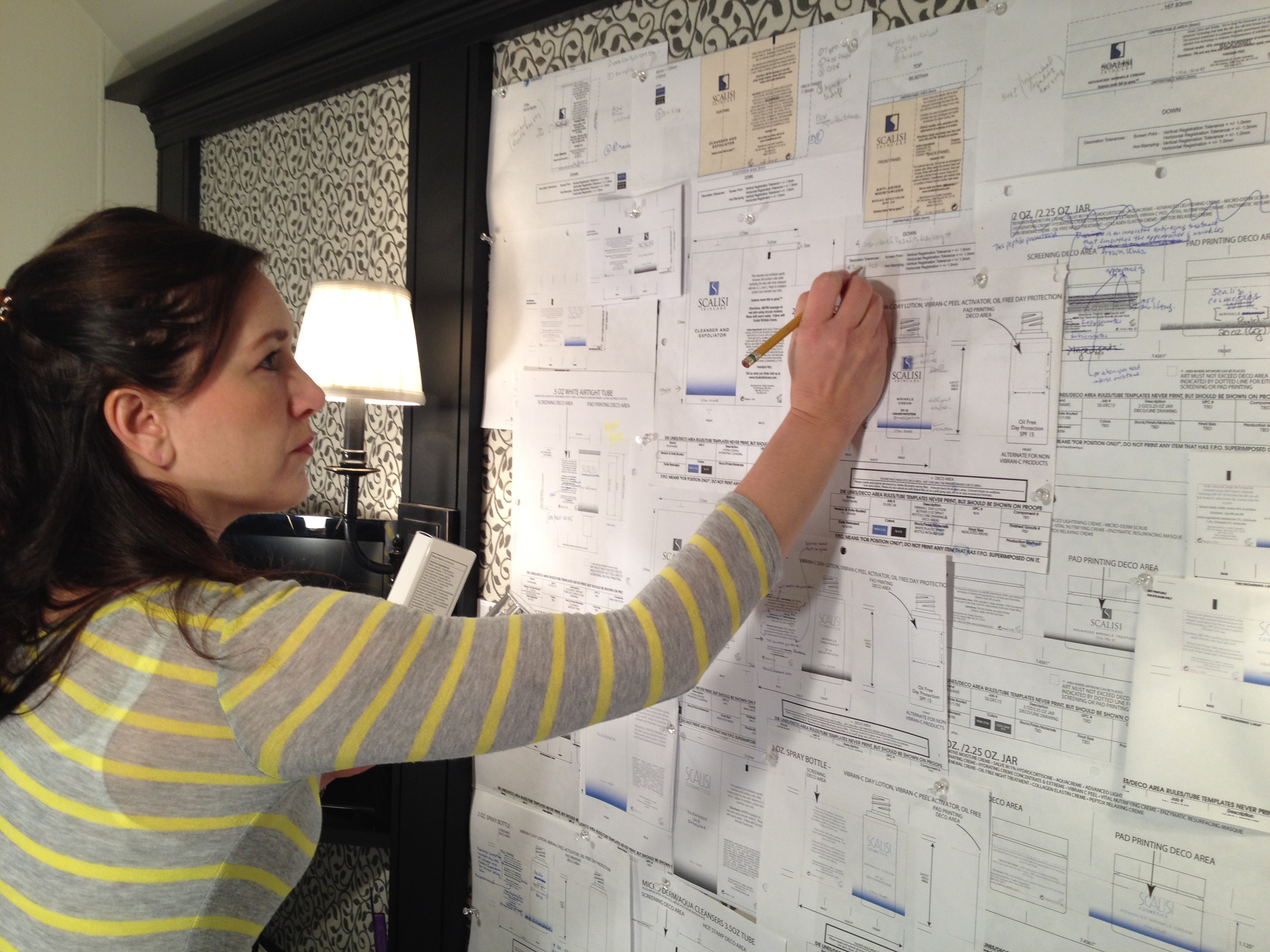

Using our signature product as an example, the wrinkle cream with SPF 30, here are the steps needed, and in this order. If the product fails any step along the way, reformulation is required and then you go back to step 1.

1. Repeat Insult Patch Test (RIPT) - 2 months - this test is conducted on individuals where the product is applied to the skin and covered with a patch. The subject is later checked for any sensitivity to the skin. This process is repeated throughout 8-9 weeks.

2. Micro Challenge - 2 months - this test verifies that the preservatives used in the product are capable of fighting off bacteria when introduced to the formula.

3. Stability - 3 months - conducted in a glass jar - this test makes sure the product doesn't break down over time.

4. Compatibility - 1 month - conducted in the packaging to be used - this test makes sure the formula doesn't react (i.e. chemical reaction) to the ingredients in the packaging.

5. SPF and Critical Wavelength - 2 weeks - testing is done on actual subjects - this tests to make sure the product meets the guidelines for Broad Spectrum (UVA and UVB) recently released by the FDA (see Blog dated June 15th FDA Regulation Means an Even Playing Field).

6. Engineering - 1 week - the engineers make sure the component is compatible with the production line as well as testing the evacuation process.

Read more: Bottle Options and Supply Chain Management

[…] Read more: How a Formula becomes a Product […]

Great for you that you are about to launch..no easy work and a path only a few would dare venture. As you know, the beauty world is very competitive. It has now reached the point where the companies are no longer competing based on quality -it is already a given especially with the astronomical research budgets of cosmetic giants like Estee Lauder, Shiseido,etc. But just three things since you are about to launch your line: 1) Work on a story/heritage behind your line. That’s where you can compete with the giants. Like for instance, Creme de la Mer (owned by Estee) used a story about the cream being used to heal scars, L’Occitane uses Provence as a backdrop of their products,Nars would name his colors after movies, Origins (owned by Estee) sets itself apart.. you must know what I am talking about. People like stories and it is all about marketing to differentiate you brand and sell. 2) Use power of celebrities. Give your products away in the beginning. 3)Third, do not aim to compete against the giants but rather, aim to be bought by one of them. A bit of trivia-Francois Nars bought an island after he was bought by Shiseido. Good luck!